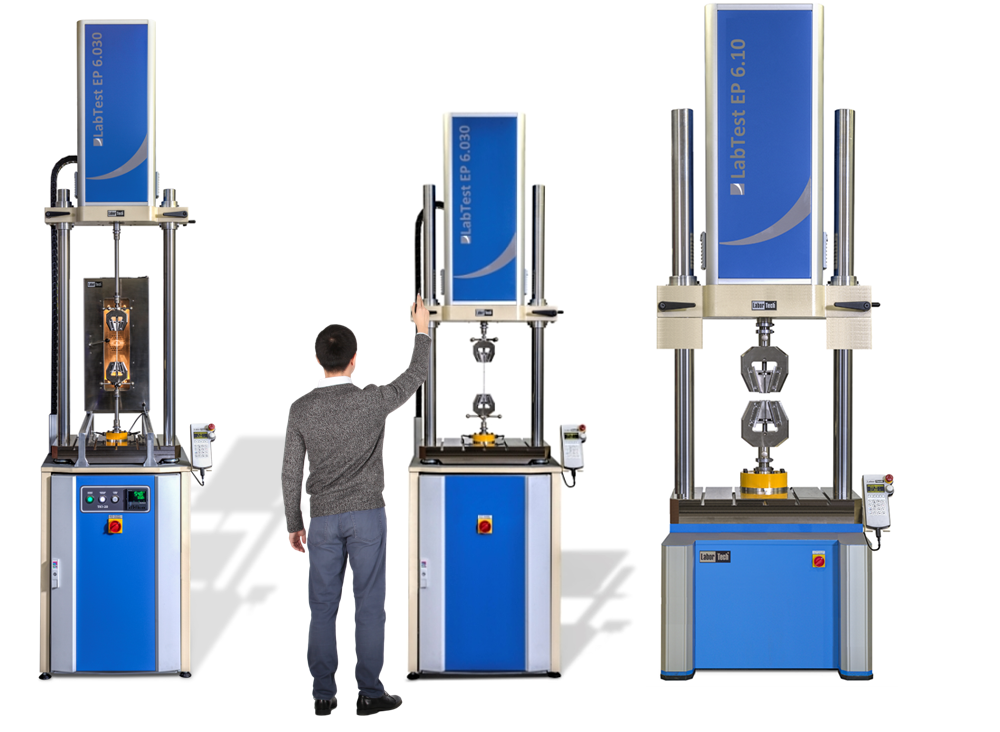

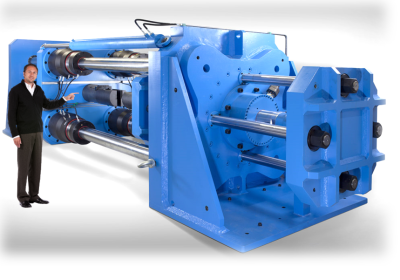

Dynamic and fatigue testing machines

We offers comprehensive solutions for dynamic and fatigue testing of materials. Their wide range of fully integrated testing systems includes servo-hydraulic, servo-electric and linear actuators with capacities from 500N to 2 MN. These systems are designed to reliably perform high-cycle and low-cycle fatigue tests, crack propagation and growth tests, biaxial and axial-torsional tests and fracture toughness evaluation.

We emphasizes intuitive and seamless operation of its testing software, which ensures reliable connection to the corporate network and allows easy expansion with a wide range of accessories. Thanks to this, users can efficiently perform testing in accordance with international standards:

ISO 12106 – Low-cycle fatigue testing of metallic materials under strain control, ASTM E606 – Standard test method for strain-controlled fatigue testing, DIN 50100 – Testing of metallic materials using the Wöhler curve method, ASTM E399 – Determination of fracture toughness using the K_IC method, ASTM E647 – Determination of fatigue crack propagation rate, ASTM E466 – Standard test method for axial fatigue testing, etc..

The products offered include, for example: servo-hydraulic testing machines, axial-torsional servo-hydraulic testing machines, biaxial and triaxial testing machines, or electrodynamic testing machines with testing frequencies up to 200 Hz. Each of these systems is designed with the specific requirements of various industries in mind, ensuring their versatility and high functionality.

Thanks to many years of experience and continuous development, we offers reliable and modern solutions for dynamic and fatigue testing of materials that meet the highest standards of quality and safety.